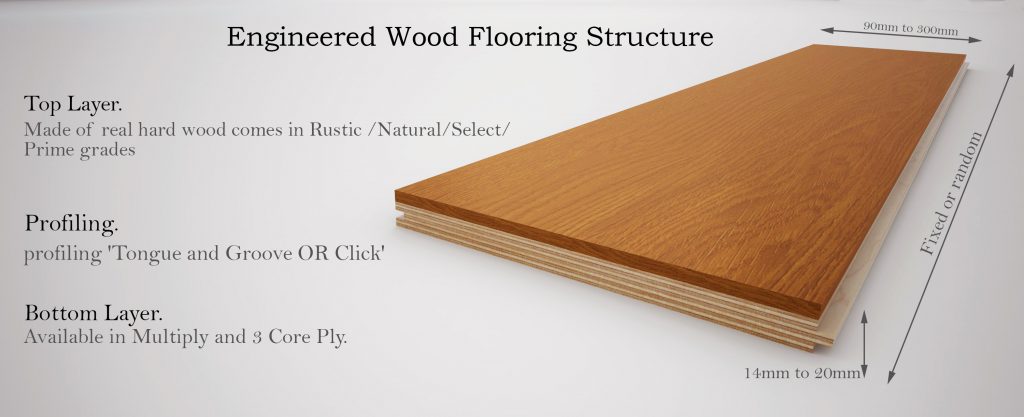

The entire plank is made from wood, it is the only material used in the manufacturing of hardwood floors. Modern hardwood is typically made with a tongue and groove system for easy installation . Hardwood floor is easy to sand and refinish, and requires a healthy amount of maintenance to keep them looking great. They are easier to damage than the two other floor types discussed here though, so buyer beware. Not only do they dent easier (i.e. if you walk with stilettos or drop a heavy object on the floor you’ll see dents), they cannot be left wet or else they’ll become damaged (the boards will swell and expand).

Hardwood flooring is almost always more expensive but no one can argue how gorgeous it looks or feels when you walk on it.